A report recently published by researchers from the University of Colorado has generated considerable buzz within the high performance construction industry. According to Matthew Hallowell, assistant professor of Civil, Environmental and Architectural Engineering at the University of Colorado Boulder, he and his fellow researchers found that LEED construction locations had a 50 percent higher injury rate than non-LEED sites. Hallowell and his team visited and made observations at various LEED and non-LEED construction sites, pored over injury reports, and conducted interviews in their process of completing their study.

The report is interesting and provocative. I would like to highlight a key finding from the report, the summary of key findings from which follows. Prefabrication of buildings such as the modular construction techniques we use here at Capsys may greatly or mitigate many of these increased risks.

We thank the author for his work and suggest that you readers seek out the entire report and form your own conclusions

Key Findings from Research:

Design for Safety Techniques for Green Building Components

Reports and Authors:

Collective results of this study have been organized into three manuscripts, which have been

accepted or are in review by the Journal of Construction Engineering and Management:

Safety Risk Identification for High Performance Sustainable Building Construction

Bernard R. Fortunato III, Matthew R. Hallowell, Michael Behm, Katherine Dewlaney

Safety Risk Quantification for High Performance Sustainable Building Construction

Katherine S. Dewlaney, Matthew R. Hallowell, and Bernard R. Fortunato III

Safety Risk Mitigation for High Performance Sustainable Building Construction

Katherine S. Dewlaney and Matthew R. Hallowell

Overview:

The US Green Building Council’s Leadership in Energy and Environmental Design

(LEED) program represents the largest program in the United States for the measurement,

verification, and certification of green buildings. A recent study found that LEED certified

buildings have a recordable injury rate that is 9% higher than traditional, non-LEED

buildings. This finding served as the impetus for the present study, which aimed to (1)

identify and evaluate the safety and health risks associated with the design elements and

construction management practices implemented to achieve LEED certification by

conducting eight detailed case studies; (2) quantify the percent increase in base-level

safety risk through 37 interviews with designers and contractors who had completed an

average of four LEED projects and 100 traditional projects in their average of 18 years of

experience in the architecture, engineering, and construction industry; and (3) identify and

describe strategies that reduce the safety risk associated with the design and construction

of high performance sustainable projects by conducting 26 additional interviews with

experienced designers and constructors. The study revealed 12 LEED credits that

increase safety risks on construction projects when compared with traditional, non-LEED

alternatives. The study also revealed that there are feasible prevention through design

techniques, technologies and controls, and management strategies that can be

implemented to mitigate these risks. The results of the study were packaged into a first-generation decision support tool that provides designers and construction managers with

safety suggestions for their LEED projects.

Workers on LEED construction projects are exposed to work at height, with

electrical current, near unstable soils, and near heavy equipment for a greater

period of time than on traditional projects.

Workers are exposed to new high risk tasks such as constructing atria, installing

vegetated roofs, and installing photovoltaic (PV) panels that are not present on

traditional projects.

The most significant impacts are a 36% increase in lacerations, strains and

sprains from recycling construction materials; a 24% increase in falls to lower

level during roof work because of the installation of on-site renewable energy

(e.g., PV panels); a 19% increase in eye strain when installing reflective roof

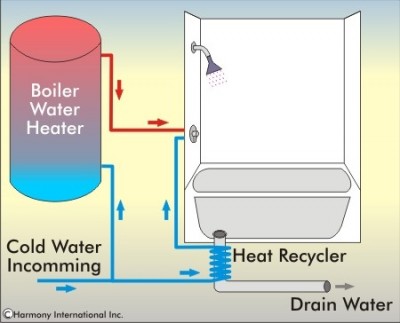

membranes; and a 14% increase in exposure to harmful substances when

installing innovative wastewater technologies.

Designers and contractors identified prefabrication, effective site layout, and alternative products as methods to prevent injuries that specifically relate the hazards of each sustainable element.

Specifying low VOC materials reduces health-related risks for construction workers

who perform work in enclosed environments.

Conclusions:

This research has revealed the substantial need for a detailed lifecycle analysis of

the safety impacts of high risk and common sustainable building technologies.

Although these technologies may have substantial environmental benefits, many

have been shown to result in greater exposures to known occupational hazards

during the construction process. Further research is needed to evaluate the safety

risks during manufacturing of sustainable materials, shipping, installation, and

maintenance.

For more information, contact the lead author:

Matthew.hallowell@colorado.edu

© Copyright 2011, CPWR – The Center for Construction Research and Training. All rights reserved This research

and report was funded by CPWR – The Center for Construction Research and Training as part of a cooperative

agreement with the National Institute for Occupational Safety and Health, NIOSH (OH009762). The research is

solely the responsibility of the authors and does not necessarily represent the official views of NIOSH. CPWR, the

research and training arm of the Building and Construction Trades Department, AFL-CIO, is uniquely situated to

serve workers, contractors, and the scientific community. For more information, visit www.cpwr.com