The Capsys Process

The Capsys Process is the set of procedures and practices we have developed to ensure that each module of every project moves in a well thought-out way from inception to finished building. Our construction process, fully adapted to the needs of the assembly line, is a sequence of steps that ensures that all of the necessary design detail is present at the beginning of the process, and is built into each module in an orderly sequence as it works its way down the line.

These are some of the critical aspects of this process:

- Validation

Before beginning any project we ensure that there is a good fit between the proposed building's structure and the dimensional relationships that are required for efficient and effective modular realization. - Coordination of Onsite and Offsite Activities

In our experience the most under-appreciated requirement of the modular construction process is the necessity for good coordination between the Capsys offsite team and the various parties that make up the onsite team over the course of the project.

This part of the Capsys Process provides a plan to guide the project from the preparation of the site, through the orderly erection of the modules at the site, to the integration of all the elements into the finished building. - The Design Process

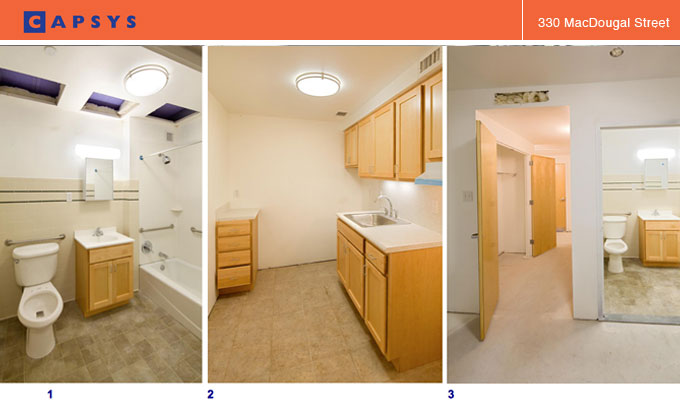

This part of the process is designed to ensure that the owner’s and the architect’s initial building concept is faithfully translated into a modular construction that satisfies both their requirements and the requirements of the modular construction process. - Fabrication

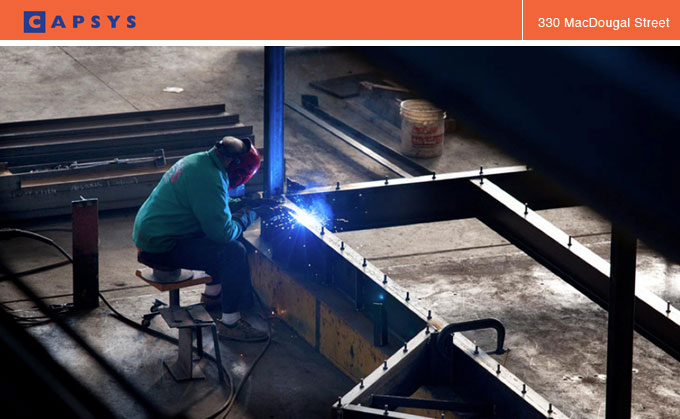

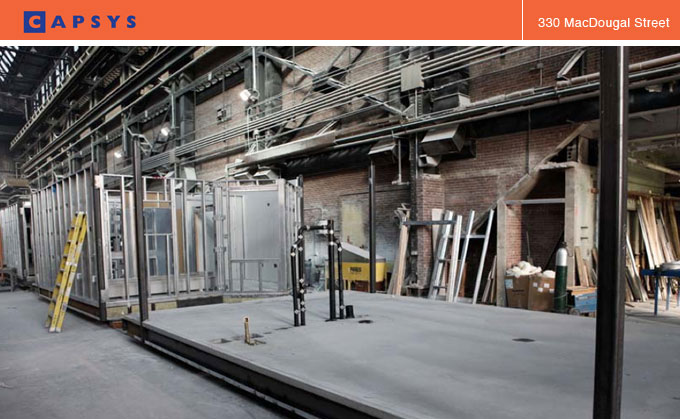

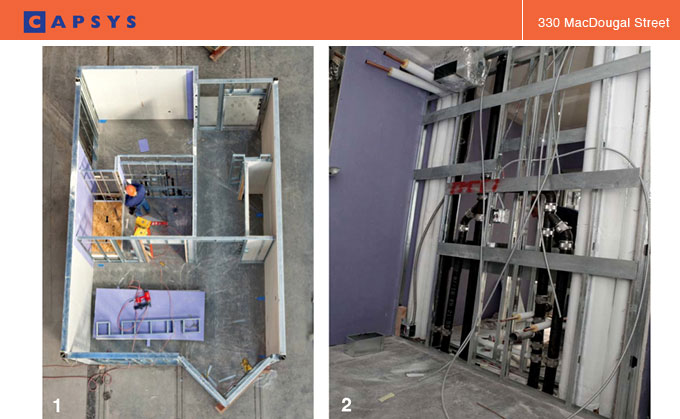

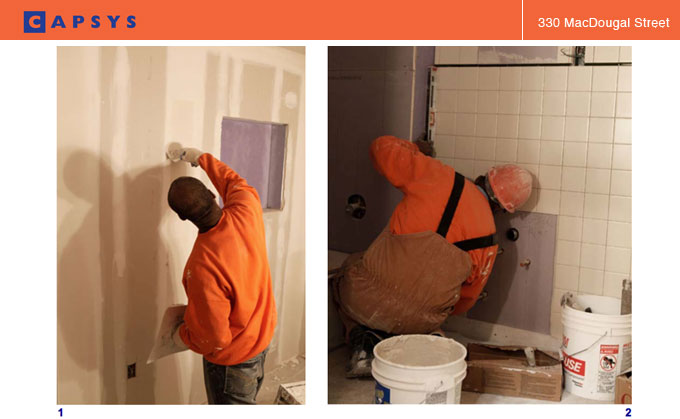

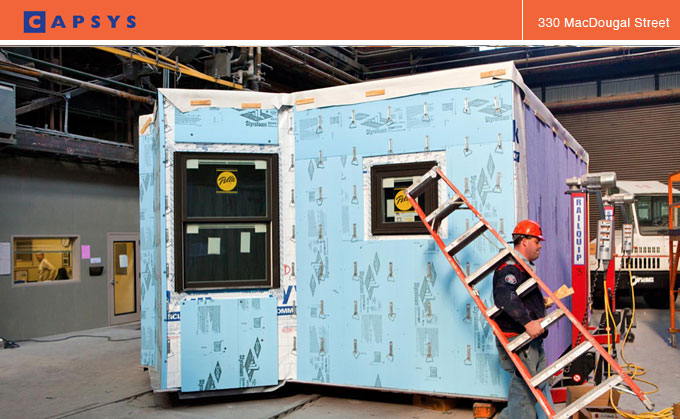

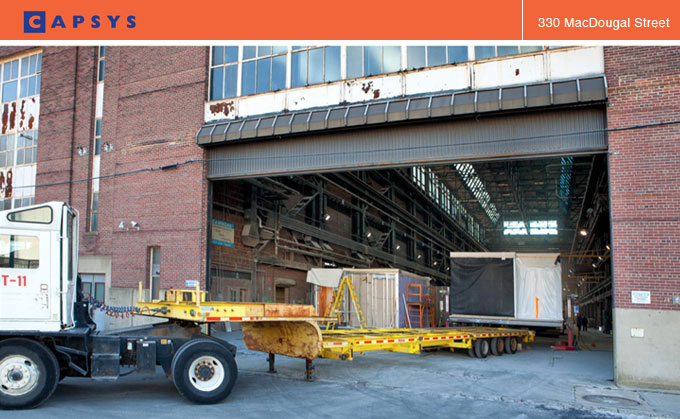

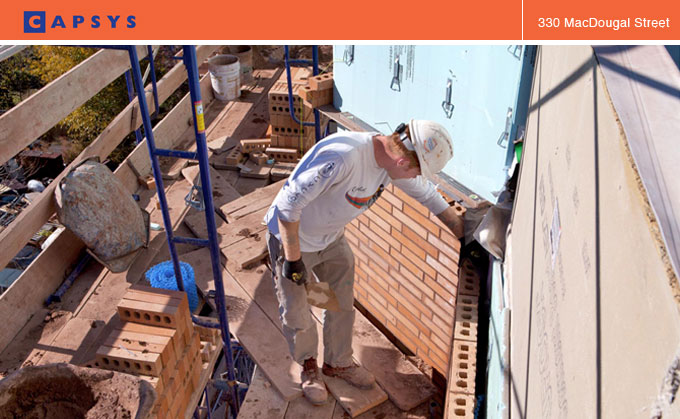

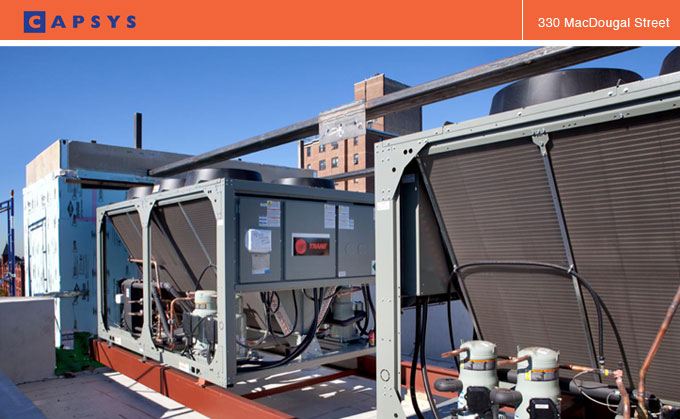

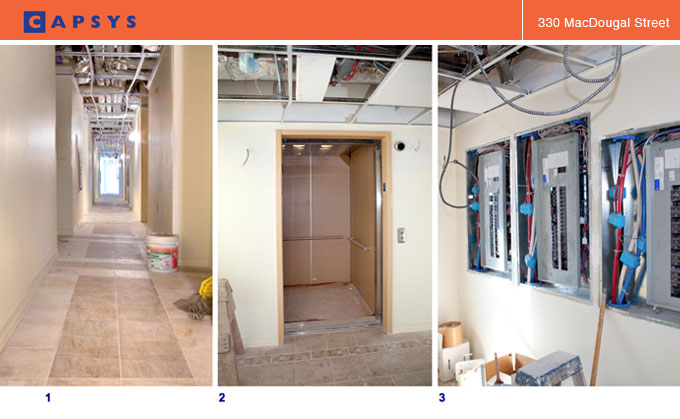

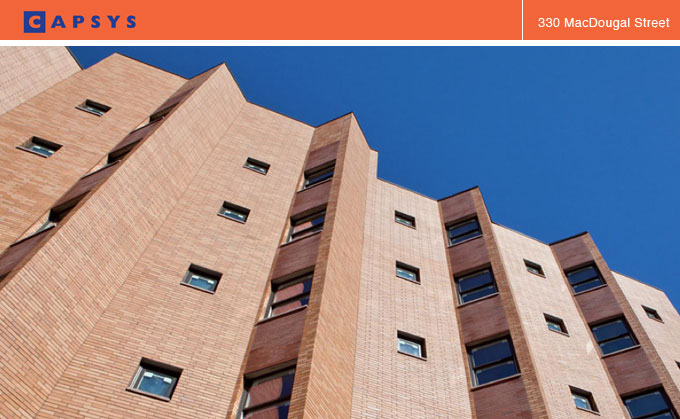

The Capsys modular fabrication process takes place within our 75,000 SF climate controlled production facility located within the Brooklyn Navy Yard. The process moves construction off site to bring the order and control of an assembly line to the often chaotic craft/trade building system of a typical on site construction project. Our Union affiliated workforce take up their positions at stations near the materials and tools needed for their tasks. The building, in modular sections, moves from station to station coming to the workers rather that the workers moving throughout the building. Starting with the fabrication of the structural elements, components are added to the modules as they move through the factory. Windows, doors, MEP systems and fixtures, and trims are all installed along the line. The modules are then wrapped in protective materials and moved to temporary storage awaiting their trip to the building site to become part of the building project.

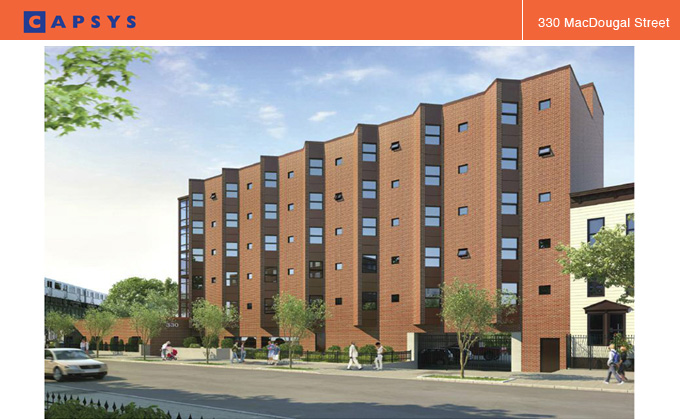

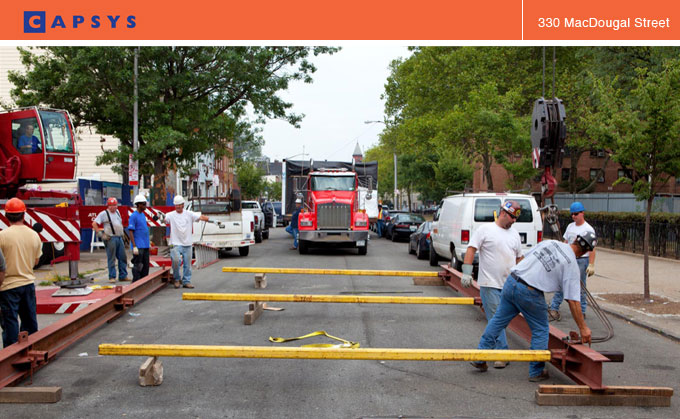

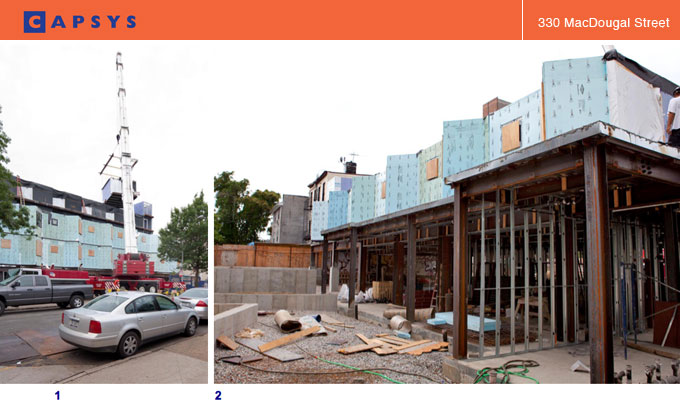

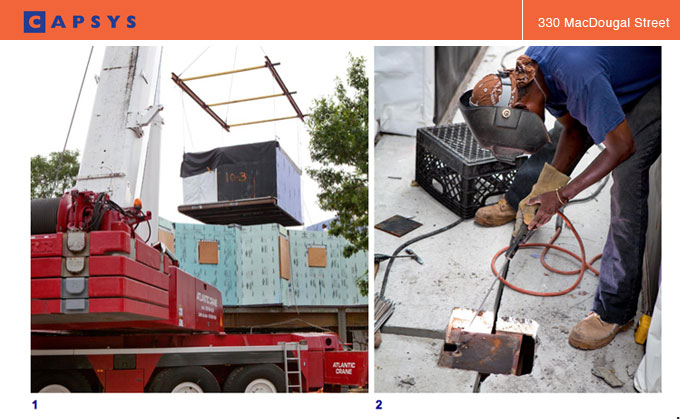

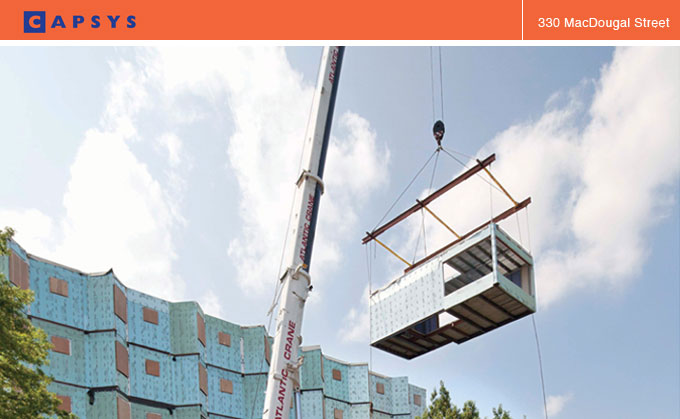

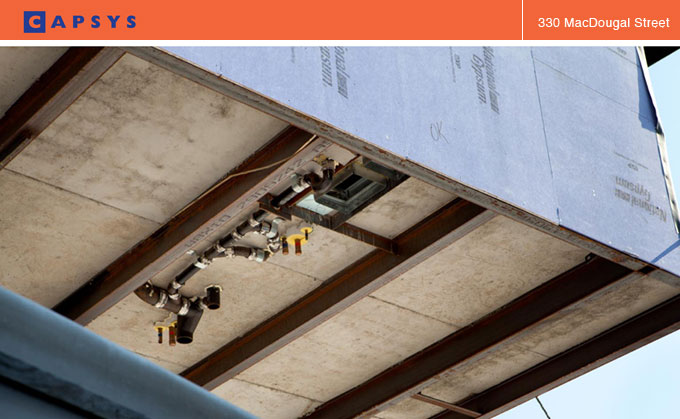

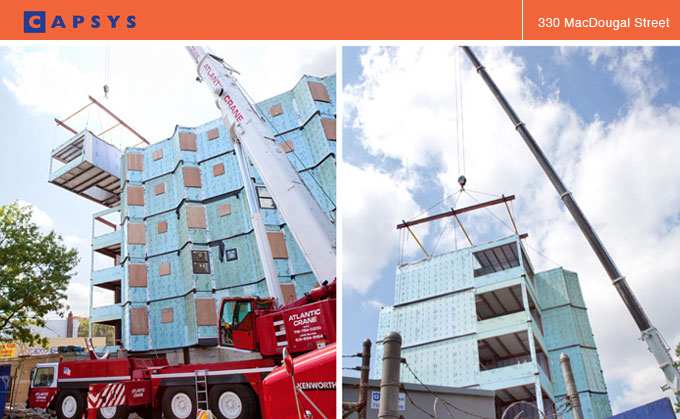

While the site is being prepared and the foundations constructed, Capsys is fabricating the modules. When the site is prepared, a special team of Capsys modular erectors mobilize the setting scheme. A large hydraulic construction crane is staged to the site, modules are transported in a systematic order to the crane hook and modules are quickly stacked and welded to interconnect the modules into a unitized structural whole assembly. The erection process happens quickly, usually within a matter of a few weeks. The erection process happens quickly, usually within a matter of a few weeks.

- Time

One of the inherent benefits of the Capsys Process is the speed with which modules can come off the assembly line. This results in minimizing the time between project inception and, for example, a hotel being open for business.

The modules for a 50,000 square foot building can be done in 8 – 10 weeks.

Click Contact Us for more information about The Capsys Process.